Photo: © Kronprins Haakon

The ship is dedicated to marine research so its thrusters maximise the reduction of noise and vibration

Alconza has designed and manufactured the two propulsion motors for the new icebreaker Kronprins Haakon; whose shipowners are the Norwegian Polar Institute, and is designed for marine research. The propulsion motors have a power of 5700 KW – 7650 HP, and among other characteristics, meet the standards established for E0, Class 3 Shipping (PC3: Polar Class 3) and CMF-V(3). With these motors, Alconza seeks the best mechanical features while offering the crew maximum comfort thanks to low noise and vibrations. Moreover, marine environment friendliness was not ignored when designing them, since a silent vessel with few vibrations has been achieved so as not to alter the marine biomass.

Maximum on board comfort is sought with the CMF-V(3) standard, so Alconza specialists paid maximum attention to the design and testing of each motor, thereby enabling them to guarantee the lower noise emissions and vibrations than usual for these motors with this performance level.

The low noise and vibration levels were achieved thanks to a rigid connection with the motor mount, a solution which simplified its assembly inside the ship, while at the same time facilitating calculation of the axis lines. Furthermore, it is a more economical solution than that of fitting the motor over elastic supports.

These motors also meet the E0 requisites, designed for ships whose machinery is not constantly attended; and as such, Alconza has provided the motors with reliability and monitorization at all times.

The Polar Class 3 refers to navigation all year long through ice in its second year of freezing, which may include pieces of ice that are several years old. To tackle these navigation conditions, Alconza engineers applied a special design criterion from the mechanical and thermal viewpoint of the motors.

All these characteristics together are designed to obtain a ship capable of carrying out its main purpose, i.e. research, in the best possible conditions. Alconza have paid special attention to ensure the scientists on board will not have their analyses or calculations affected by noise and vibrations from the propulsion system. Low vibrations are also beneficial for the marine biomass, since animals such as whales, will be unaffected by the ship travelling across the surface.

Another feature worth highlighting regarding the motors is their system of bearings, designed to work at very low revolutions per minute (RPM), thanks to the inclusion of a hydrostatic system. To increase the safety of the bearing system and ensure lubrication of the same, the corresponding emergency pumps were installed.

Lastly, Alconza was able to overcome the strict conditions established for the inclinations of both motors, so they can adjust to static inclinations of up to 15º and 22º in dynamic.

The entire technical specifications which the icebreaker motors meet are: DNV Certificated. DNV + 1A1, E0, RP, NAUT-OSV, CLEAN DESIGN, PC-3 ICEBREAKER, DAT (-35ºC), WINTERIZED BASIC, HELDK-SHF, DYNPOS-AUTS, COMF-V (3)/C (2) and DK (+).

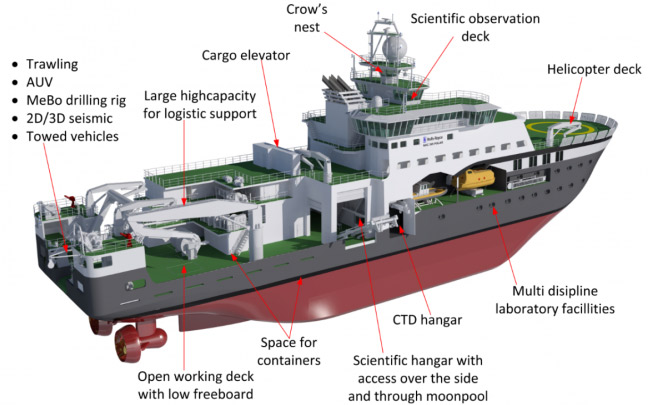

The Kronprins Haakon ship was built at Fincantieri shipbuilders with headquarters in Trieste (Italy) for Rolls Royce Marine; and is equipped with the most avant-garde instrumentation in marine research and is designed to operate all year round in ice covered waters.